High-Quality Accessories for Enhanced Performance and Efficiency

IMDC offers a comprehensive range of high-quality mold and die accessories including Ejector Pins, Sleeves, Sprue Bushes, Guide Pillars, Guide Bushes, Locating Rings, and more. Our accessories are manufactured with stringent quality controls, ensuring reliability and performance.

Our Accessories

Dowel Pins

IMDC’s dowel pins are precision-engineered to ensure accurate alignment of mold components. Made from high-grade alloy steel, these pins are hardened and ground to tight tolerances, ensuring consistent performance.

Features:

- Material: High-grade alloy steel

- Hardness: 60 ±2 HRC

- Precision-ground for tight tolerances

- Available in various sizes and lengths

Applications:

Essential for aligning mold plates and components, ensuring repeatable and accurate mold assembly.

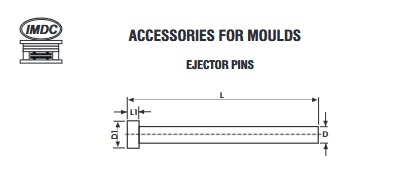

Ejector Pins

IMDC’s ejector pins are crafted from premium H13 hotwork die steel, ensuring durability and precision in injection molding applications. Our pins undergo a nitriding process, achieving a surface hardness of 65-70 HRC, which minimizes wear and extends tool life. The core hardness of 47-52 HRC provides resistance against bending and deformation.

Features:

- Material: Premium H13 steel

- Surface Hardness: 65-70 HRC (nitrided)

- Core Hardness: 47-52 HRC

- Centerless ground for precise fit

- Annealed heads for easy machining

Applications:

Suitable for molds requiring stepped ejection, providing stability and reducing the risk of pin deformation.

Shoulder Ejector Pins

Our shoulder ejector pins are designed for applications requiring precise ejection with added strength at the shoulder junction. Manufactured from high-grade H13 steel, these pins offer excellent wear resistance and longevity.

Features:

- Material: High-grade H13 steel

- Surface Hardness: 65-70 HRC

- Core Hardness: 47-52 HRC

- Precision-ground diameters

- Annealed heads for machinability

Applications:

Suitable for molds requiring stepped ejection, providing stability and reducing the risk of pin deformation.

Support Pillars

Our support pillars provide robust support to mold plates, preventing deflection during molding operations. Constructed from durable materials, they ensure the longevity and stability of your molds.

Features:

- Material: High-strength steel

- Precision-machined for accurate height

- Available in various diameters and lengths

Applications:

Used to support mold plates, especially in large molds, to maintain parallelism and prevent plate deflection.

Guide Bushings

IMDC’s guide bushings are designed to work seamlessly with our leader pins, ensuring precise alignment and smooth operation of mold components. Manufactured with high-quality materials, they offer excellent wear resistance and longevity.

Features:

- Material: Bronze-plated steel

- Self-lubricating properties

- Precision-machined for tight fit

- Available in straight and shoulder types

Applications:

Ensures accurate alignment of moving mold components, reducing wear and extending mold life.

Sprue Bushings

Our sprue bushings are engineered to facilitate the flow of molten plastic into the mold cavity. Crafted from hardened steel, they withstand high temperatures and pressures, ensuring consistent performance.

Features:

- Material: Hardened tool steel

- Tapered design for optimal flow

- Polished interior surface

- Available in various sizes and configurations

Applications:

Directs molten plastic from the injection nozzle into the mold cavity, ensuring efficient and defect-free molding.

Ejector Sleeves & Extensions

Our ejector sleeves and extensions are designed to work in tandem with ejector pins, facilitating the smooth ejection of molded parts. Manufactured with precision, they ensure seamless operation and longevity.

Features:

- Material: High-quality steel

- Inner surfaces honed for smooth pin movement

- Available in various lengths and diameters

- Heat-treated for enhanced durability

Applications:

Ideal for applications where extended reach is required for part ejection, ensuring consistent and efficient mold operations.

Round Punches

Round punches are critical precision tools in metalworking, specifically used to make clean, precise holes in materials. Used mainly in stamping, punching, and shaping operations, round punches deliver consistent performance in high-pressure applications. Made of long-lasting materials such as steel or carbide, round punches guarantee longevity and consistent quality, making them a necessity in industries like automotive and aerospace.

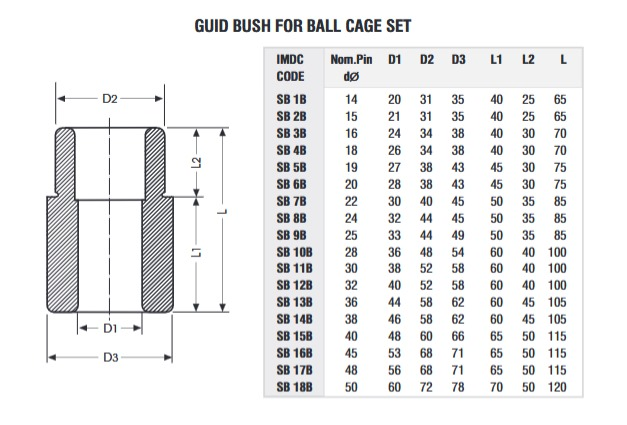

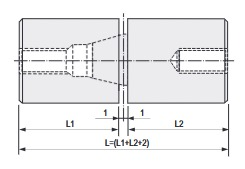

Ball Cages Set

Our premium ball cages are precision machined for optimum efficiency, with low friction and wear. Engineered for durability and reliability, they perform better in demanding applications, providing silky smooth motion under both standard and high-performance conditions.

Compatible Accessories for Tooling, Molding, and Machinery

Our compatible accessories are crafted to integrate effortlessly with a wide range of tooling, molding, and machinery systems. Built with precision and endurance, they maximize operational effectiveness, minimize downtime, and provide consistent performance. From upgrading current installations to installing new systems, our accessories deliver the reliability and flexibility required to support the requirements of contemporary manufacturing environments in diverse industries.