High-Precision Dowels for Accurate Alignment and Positioning

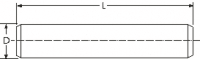

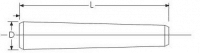

We offer a comprehensive selection of dowel pins, including cylindrical and tapered variants. Precision manufactured from hardened alloy steel, IMDC dowel pins provide accurate alignment and maintain structural integrity across a wide range of mold and die applications.

Understanding the Role of Dowels in Precision Engineering

Features:

- Material: High-grade alloy steel

- Hardness: 60 ±2 HRC

- Precision-ground for tight tolerances

- Available in various sizes and lengths

Dowels in Product Manufacturing

Benefits of Using Dowels in Industrial Applications

Essential for aligning mold plates and components, ensuring repeatable and accurate mold assembly.

Precise Positioning

Provides ideal part alignment for assembly.

Increased Stability

Avoids movement or shifting of components.

Reduced Wear

Reduces friction between mating parts.

Efficient Assembly

Facilitates repeat and reliable part assembly.

High Load Capacity

Withstands mechanical stress well.

Corrosion-Resistant Options

Exists in materials that can withstand harsh environments.

Industrial Uses of Precision Dowels

Precision dowels are used in industrial assemblies for accurate alignment, secure positioning, and consistent performance in high-precision manufacturing environments.

Machine Assembly

Provides proper part alignment for heavy machinery.

Mold

Making

Ensures precise positioning of mold parts.

Tool and Die Alignment

Adds stability and consistency to die installations.

Fixture Construction

Assists in constructing precise jigs and fixtures for manufacturing.