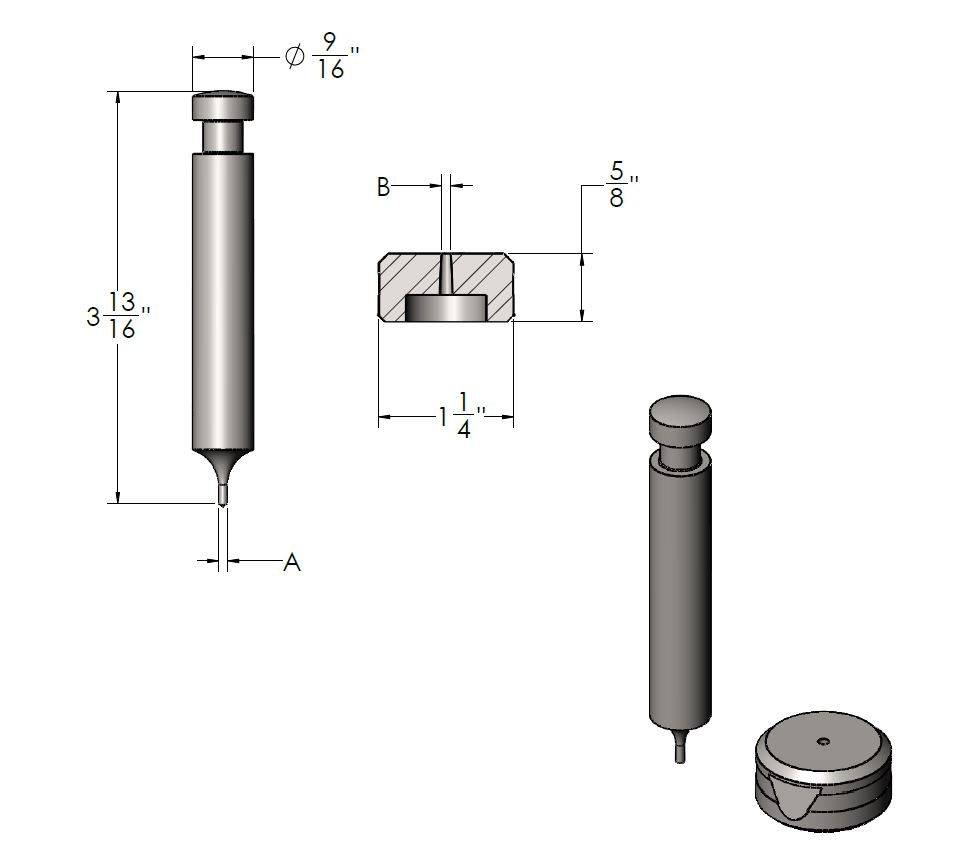

Round Punches for

Precision and Durability

Round Punches: Precision Tools for Metalworking

Ejector Pins in Product Manufacturing

Benefits of Choosing High-Precision Round Punches for Your Projects

Better Accuracy

High-precision round punches guarantee precise hole location, enhancing the overall quality and performance of your projects.

Less Material Waste

With accurate punching, less material is wasted, resulting in cost savings and more efficient production processes.

Better Durability

Constructed from durable materials such as steel or carbide, these punches are wear-resistant and provide long-lasting performance.

Improved Efficiency

Their capacity to produce clean, precise holes in a short time contributes to minimizing production time, increasing overall efficiency.

Flexibility in Applications

Suited to many industries, round punches of high precision can be applied in metalworking, autos, aerospace, and other fields.

Consistency in Production

The punches deliver consistent, repeatable performance, allowing for consistency and uniformity across many production runs.

Key Applications of Round Punches in Manufacturing

Metal

Stamping

Produces precise holes and shapes in sheet metal.

Production of Automotive Parts

Provides accuracy in parts such as brackets and panels.

Electronics Manufacturing

Applied to punch micro-components as well as circuit board features.

Aerospace Fabrication

Provides clean cuts in high-strength material with tight tolerance.